High Alumina Chequer Firebrick

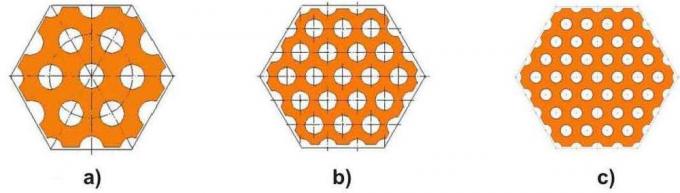

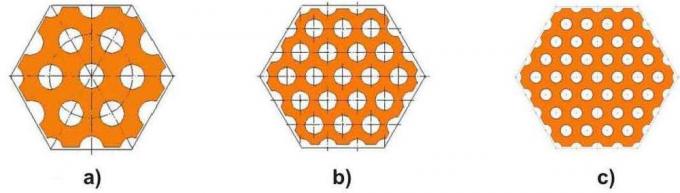

Choose the type what you need, or provide the size you need.

High Alumina Chequer Firebrick Features & Advantages

High Alumina Chequer Firebrick Features & Advantages

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

High Alumina Chequer Firebrick for Furnace Technique Data

| High Alumina Chequer Firebrick Physical and Chemical Index: |

| Item |

Properties |

| RS-80 |

RS-75 |

RS-65 |

RS-55 |

RS-48 |

| Al2O3 (%) |

80 |

≥75 |

≥65 |

≥55 |

≥48 |

| Refractoriness (°C ) |

≥1790 |

≥1790 |

≥1790 |

≥1770 |

≥1750 |

| Bulk density (g/cm3) |

2.65 |

2.5 |

2.45 |

2.4 |

2.3 |

| Softening temperature under load (°C ) |

1530 |

≥1520 |

≥1500 |

≥1470 |

≥1420 |

| Linear changes on reheating (%) |

1500°CX2H |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

| 1450°CX2H |

-0.4 |

-0.4 |

-0.4 |

-0.4 |

-0.4 |

| Apparent porosity (%) |

22 |

≤23 |

≤23 |

≤22 |

≤22 |

| Cold crushing strength (Mpa) |

55 |

≥50 |

≥45 |

≥40 |

≥35 |

| Application |

steel furnace, glass furnace, sodium silicate furnace, ceramic shuttle kiln, cement rotary kiln, blast furnace, electric furnace, blast furnace and reverberatory furnace. |

High Alumina Chequer Firebrick Applications

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Why Choose Rongsheng Kiln Refractory Manufacturer

Provide satisfactory service to you.

Quality is our culture.

With us you money is safe, business is safe.

We specialize in refractory products for nearly 20 years.

About Rongsheng Kiln Refractory Company

Zhengzhou Rongsheng Kiln Refractory Co., Ltd, located in the beautiful Xinmi CIty,Henan Province with rich refractory materials. Established in the early 90s of twenty century, with continuous innovation and development, now we are a comprehensive enterprise producing refractory in metallurgy, electirc power, building materials, chemical industry, glass, non-ferrous metals, ect. There are more than 180 staffs, including 20 professional technicians. We have 3 automatic production lines for shaped, unshaped and insulating refractory materials.